Binocular Telescope Mirrors

I received an order to

make matching focal length mirrors for a binocular, and the project intrigued

me so much I took it on. Originally, the plan was to use a single tool to grind

two mirrors going back and forth between them to keep the focal lengths as

equal as possible. But a different plan hit me. It may work, it may not, but I

have to try it. If it fails, Ill return to the standard method as mentioned

above.

The order was for two

matching 6 f/7 paraboloids. My plan

is to place three 6 disks onto a curve-generated 13.1 mirror blank with

blocking pitch and then grind them as one single optic. The 13.1 mirror blank

was curved to an ROC of 85 inches, and so when I placed the three blanks onto

it their fronts will have an ROC of about Ύ shorter, just over the 84 ROC

needed. I curve-generated a 10 tool to an 85 ROC. I then fixed-posted ground

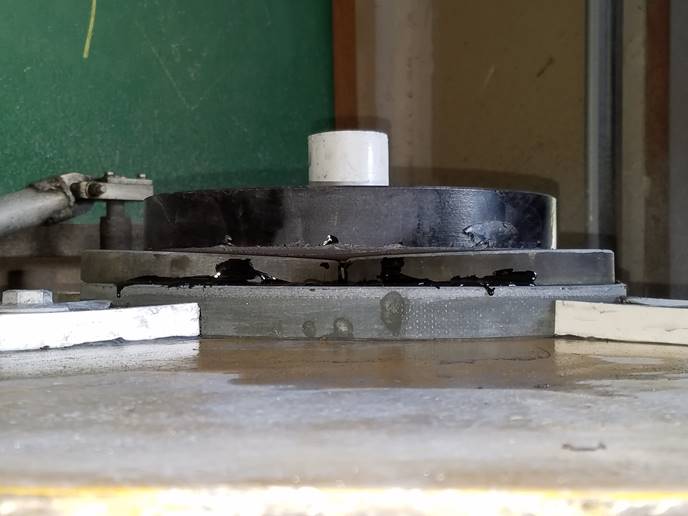

the 10 tool with the 13.1 mirror blank. If the image below you can see each f the mirrors attached to the lower glass are tilted.

Next I used blocking

pitch to secure the three 6 discs onto the 13.1 mirror. They are already

tilted with their optical axes pointing toward the center of curvature of the

13.1 master substrate. The 6 mirrors have an extremely short sagitta, so I did not pre-curve-generate them, but I beveled

their edges well and started slowly. Ill fixed-post grind them as if they were

a 13.1 mirror starting with 60 grit silicon carbide. Once ground Ill progress

through the grits as usual, 120, 220, 500, then on to

aluminum oxide with 12, 5 and 3 micron.

https://www.youtube.com/watch?v=FeB97KscL-Q

https://www.youtube.com/watch?v=4nJBCrpja_U

https://www.youtube.com/watch?v=AOWXVLzm_zY

I wanted to check to see

if there was similar grinding on each blank and if the initial grinding started

in the centers to avoid wedge. There is a bit of wedge developing, but for 6

f/7 I dont think it will be a problem. Larger mirrors might have issues. I

drew Sharpie pen lines on both the mirror set and the tool. The tool is totally

worn away, so it is getting good action. The mirror sets are showing a bit of

tilt.

I do not want to polish

them combined like this, mainly because I dont want to mess with casting a

pitch lap of a 10 tool with three 6 mirrors, thats weird. Also if there were

zoning issues, each mirror would have those zones not surrounding their

individual optical axes but rather the center of the triangular array of the

mirrors. Not cool. So I will separate them and polish them individually.

It is possible that even

though they will have identical ROCs after grinding, they may not have after

polishing. So I will select the two that are closest to each other and send

them to the customer, and keep the third as an in-stock item. The 13.1

mirror under them will also be ground, polished, parabolized and sold.

If this works out as well

as I hope it does, I have no reason why not to attempt this with larger

mirrors. As an upper limit in my brain right now, I can see three 22 f/5 mirror sitting atop a 36 f/3 mirror for the same purposes. I suppose a more reasonable set of examples

would be 8 mirrors atop a 17.5 base and 10 mirrors sitting atop a 22 base,

but larger is cool. Putting three 22 blanks atop a 36 blank and having a shop

disaster would be a financial deal-buster. Not ready for that yet. But Im

thinking about it.

I may advertise this as

being a new niche for me if this works out.

I found that the

triangular gap in the center is a place for grit to wash off the work and after

only two turns there is no more grit on the glass. So a huge amount of grt is used to do a tiny amount of work. I was puling mud

off the sides to reapply so to save on grit, but that sucked. Since I have a

large amount of material to grind away in the center of the system that was

going to take forever and use too much grit. So I poured more blocking pitch

into the central triangle to fill it in hopefully to keep this from happening.

Here is a shot of the mirrors after a bit more work and before filling in the

middle.

Notice that one mirror is

grinding well, but two are not placed on the backer sphere perfectly against it

and the mirrors are not grinding from the centers but a bit off axis. This will

result in tilt. If these are 20 mirrors, Id be re-dong this. But tiny little

6 mirrors with slight wedge is not a deal buster, especially since they will

be interferometrically tested. Once all ground, there will be many

opportunities to Sharpie test to make sure they are grinding right and fully everywhere,

hopefully implying a sphere.

Know this all looks bad but Im having a blast

processing this method.

More to come

.