Stress within Glass

can exist due to the glass solidifying and cooling from a melt too quickly. The

inside will still be amorphous after the surface has solidified, and when the

inside finally solidifies and shrinks the outside is pulled in and is now

stressed. To save this glass it can be annealed. Annealing is a process by

which the glass is heated to proper temperatures and cooled stepwise through

proper temperatures for proper times. Each glass, volume and configuration may

have specific needs for these temps, times and steps.

We at the SAS ATM do

not anneal nor have the concept and wisdom to do so, however we can test the

glass for stress and if it turns out to be stressed, you can either not work

that glass or send it somewhere to be annealed.

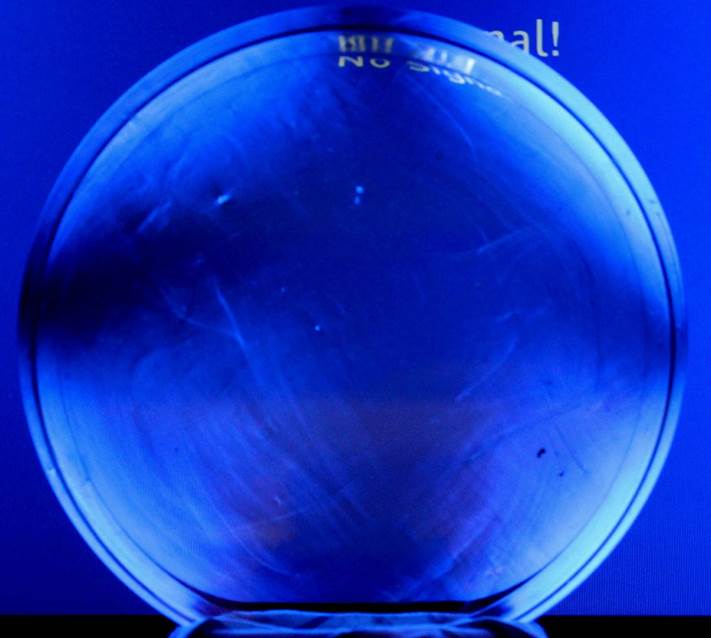

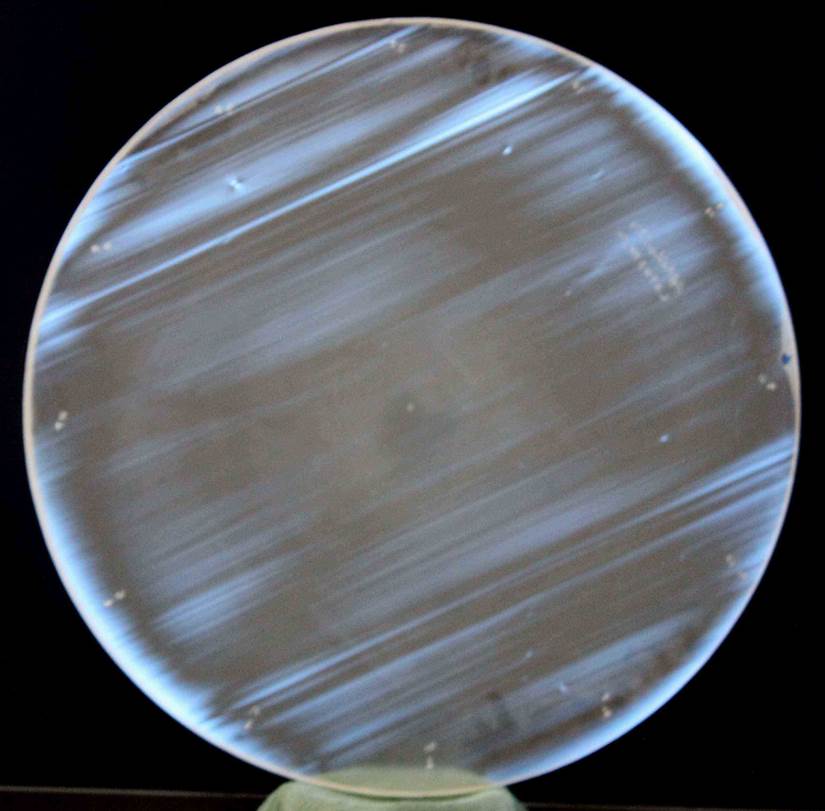

An indicator that

the mirror is under stressed is the illusion of a Maltese Cross within the

glass when viewed through polarized light with a polarization filter. Here are

some images of glass blanks in a variety of stress levels taken by us using an

LCD TV set as a rear illumination and shot through a linear polarization

filter. Many ATMers use the sky as a polarized light source and look at the

glass through a polaroid filter. It works, but the intensity and contrast of

using an LCD TV is higher. Also, the photos have been enhanced for contrast to

increase the view.

This is a 12” f/8 mirror, supposedly finished in the 1950s by

Dr. Clarence Custer of the Stockton Astronomical Society. We think the original

mirror was stolen and replaced by this inferior optic. The figure on this

mirror is zoned, under-corrected, rough and unacceptable. We will rework the

mirror regardless of the failing stress test shown here. This original mirror

served Dr. Custer for decades and was used in his famous M31 photograph

featured in Sky and Telescope magazine.

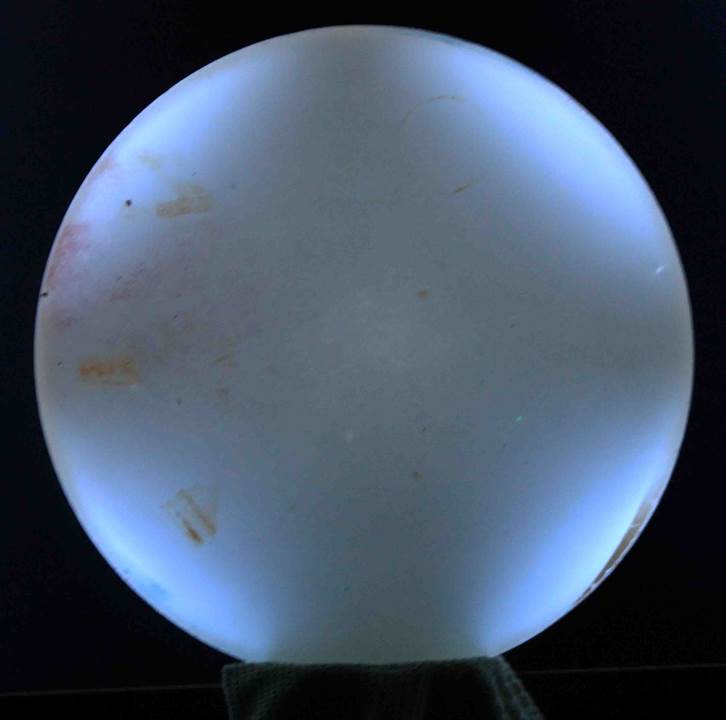

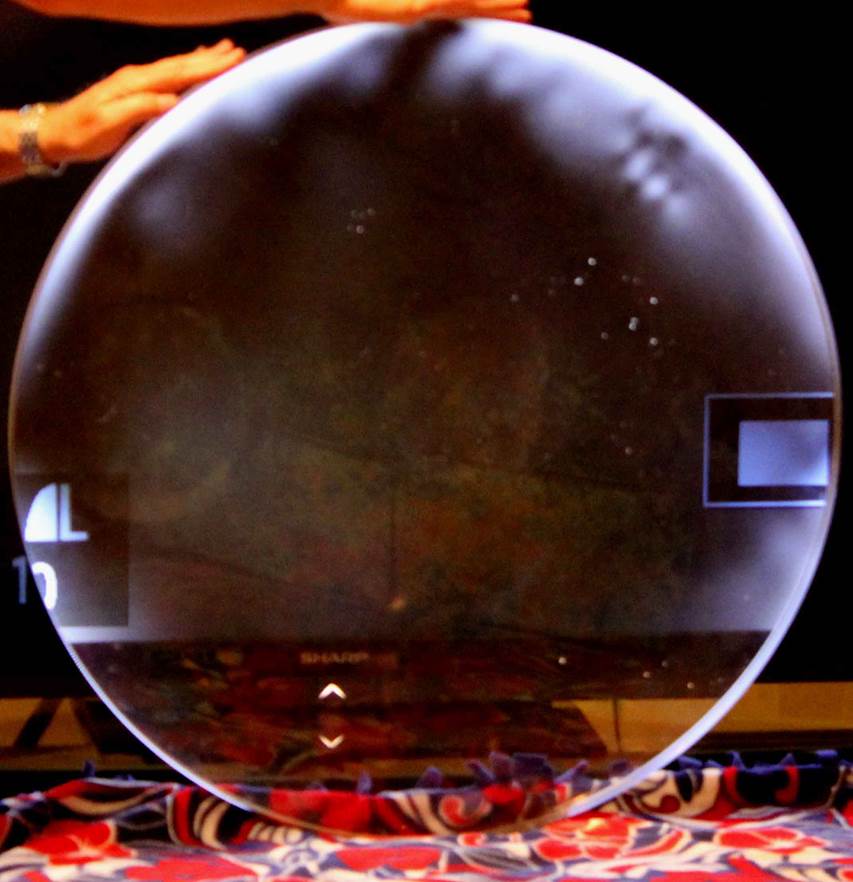

James Marino donated this thick and heavy 18” Pyrex blank to

be used in the SAS’ Bruce Orvis Memorial Telescope, an 18” Classical Cassegrain

with a Naysmith focus to be used for wheelchair-bound individuals. The mirror

will first be cored, then ground and figured to an f/1.875 Hindle Sphere

for testing the hyperboloidal secondary mirror, then reground and figured again

to its final f/3.75 configuration. It has a diamond stress test result which

is imperfect but acceptable.

A 6” blank with weird stuff in it. We think the glass was pouring

into a mold and it cooled as it was poured and was never actually annealed. Not

a good blank to work.

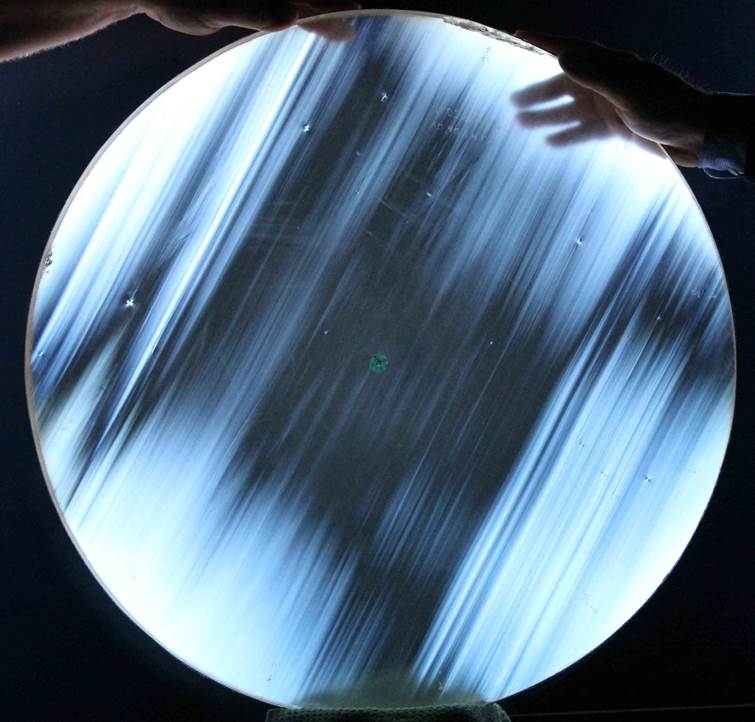

Jeff bought this blank of unknown material from Jan Bentz and

finally tried to make a mirror out of it. After working the glass three or four

times and failing due to astigmatism each time [I mean serious astig] it was

annealed at Greg’s shop. This is the strangest internal structure we’ve seen so

far.

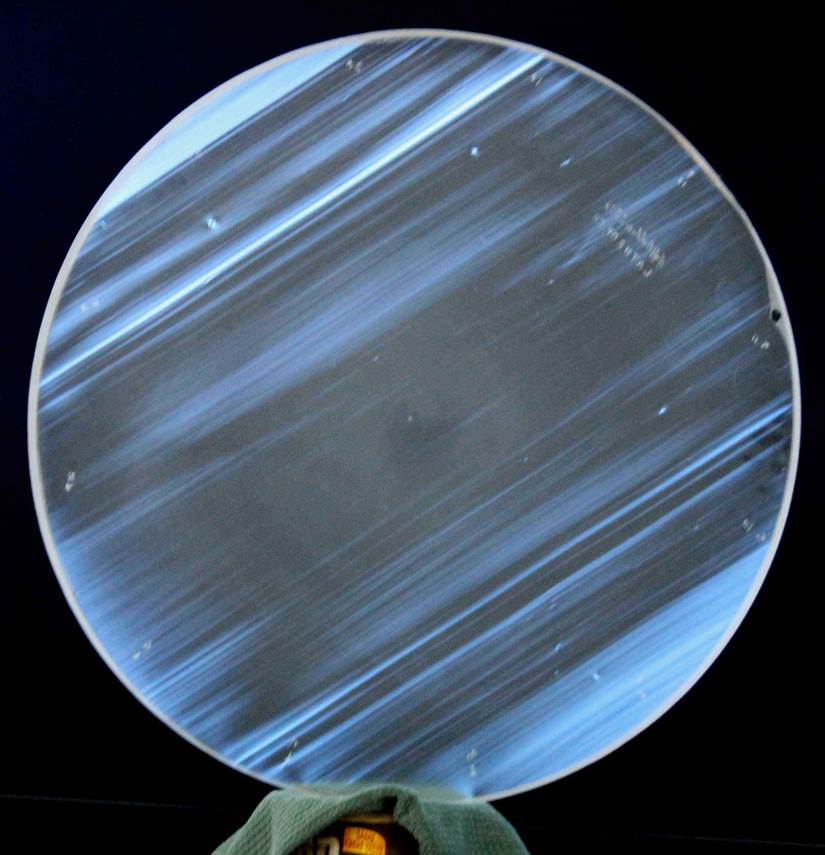

After the first anneal the main components of the cross are

gone. The strange striations in the glass are still present.

After a second anneal, the striations are still present. We

decided to work the glass anyways, and this time the astig was prevented. The

glass sat for months, and finally figured into a successful mirror.

Jeff worked three 12” quartz flats together in 2012, and

these are images of flats #2 and #3. The fused quartz were purchased from RECO

Labs and are ¾” thick. Stress is extremely minimalized. Quart is awesome stuff.

Dr. Mike Lavieri obtained a 31.5” quartz blank that Jeff will

work probably into an f/3 mirror. It’s bigger than the TV, but we can

still see the stress. It’s fine. It’s a diamond with a blemish in it.

Mike also purchased a 32” blank of borosilicate from Newport

Glass. There is more Maltese Cross present than in the locally annealed

meniscus mirrors. We’re not sure Newport anneals their glass or if their

supplier does. The mirror as figured quite well and stress was never an issue.

James Schucknecht sent Jeff a 13.1” Coulter mirror to

refigure. After many attempts the astigmatism would not go away. The mirror was

set aside. We recently tested in for stress even though the back was ground and

it is difficult to see through it. Even with a whole lot of contrast

enhancement, there isn’t much of a stress problem. So the mirror will be ground

flat on the back and retried. You can see that the mirror was ground flat on

the back but there is a bit on the left side left unground. Is that all it took

to keep this form working out? Perhaps. The mirror is now really thin, which

doesn’t help much.

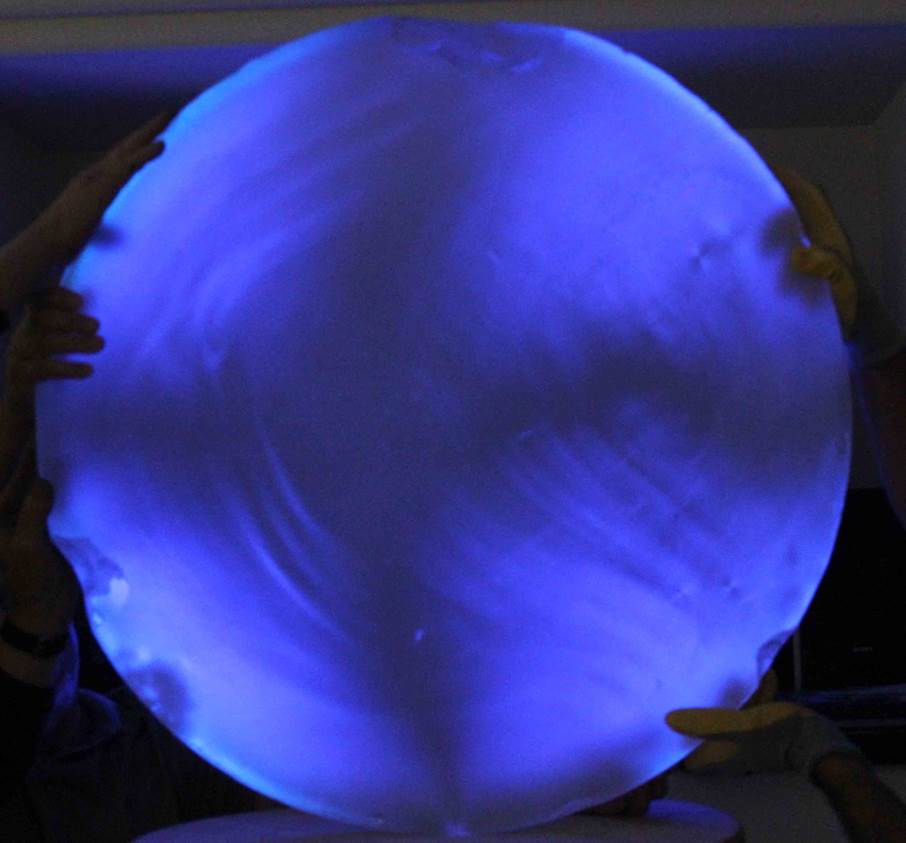

Buck Turgis from San Francisco brought one of John Dobson’s

32” blanks by the shop. It was originally 7” thick, but he had it sawn into two

32” blanks 3.5” thick. One blank was broken and “glued” together, so we denied

working on that. However, this blank, even with severe chips, was put in front

of the TV for checking for stress. The cross is obvious. Between the cross and

the chips, we decided it wouldn’t be a blank to work in the shop. There are

interesting stress flow patterns in this blank. The blank may be worked by

somebody somewhere, a large fun telescope ought to be made by somebody. This

blank was really heavy to lift up onto a stool top 5 feet above the floor to

get in front of the TV. It’s a miracle nobody died in this crazy day. What

ATMers will do. . .

A note: Buck died, Chris Pezzoni got the two glasses, and he

left one at my shop. It is useless as a mirror blank but frequently we need to

know if a process, like diamond cutting, works, and using a bad piece of glass

to do experiments on is great, so this glass is awaiting a curve-generator

method we will soon be trying. Better to do it on salvaged glass than a real

to-sell blank.